product display

product classification

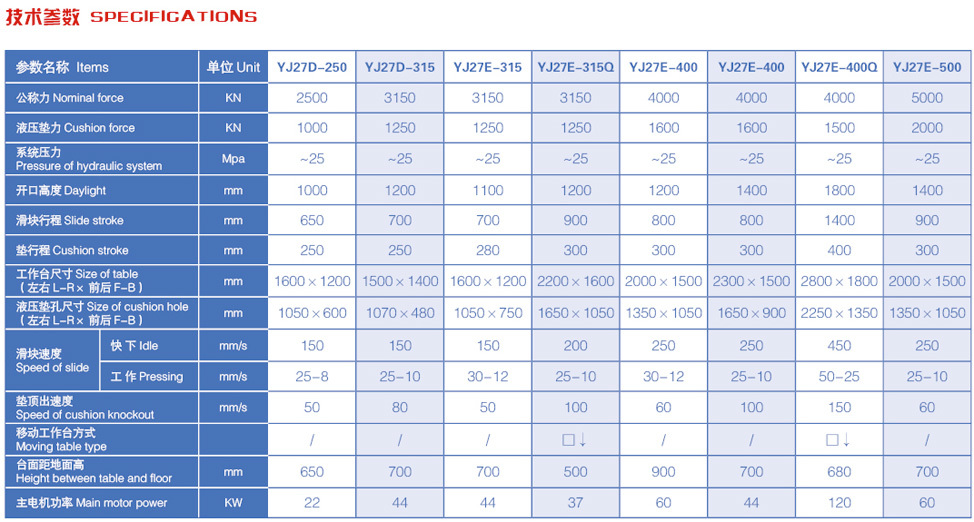

j27d、e frame single-action hydraulic drawing press

keyword: jiangsu yanggu forging machine tool co., ltd. is headquartered in the southern district of yangzhou city,

product description

1、 advantages of forging and pressing

after forging, the internal structure of steel undergoes significant changes

1. the coarse grains are crushed into small and uniform grains, which are tightly compacted together.

2. the previously existing pores or shrinkage pores disappear after being squeezed, and the internal structure becomes more compact.

3. some brittle impurities are crushed, while plastic impurities elongate with the deformation of the metal, forming fibrous structures, greatly enhancing the toughness of the material.

so, after forging, the internal structure of the material becomes very solid, significantly improving its mechanical properties.

2、 disadvantages of forging and pressing

1. due to the need for heating, forging equipment, and required molds, the manufacturing cost of forging increases.

2. there are certain limitations on the application range of materials, such as difficulty in forging high alloy steel and stainless steel. the ones with good forging properties are medium and low carbon steel.

3. there are certain limitations on the forging ratio of materials, that is, they cannot be subjected to unrestricted forging deformation.

forging and pressing are mainly classified according to the forming method and deformation temperature. according to the forming method, forging can be divided into two categories: forging and stamping; according to the deformation temperature, forging can be divided into hot forging, cold forging, warm forging, and isothermal forging. forging is carried out at a temperature lower than the recrystallization temperature of the metal. generally, cold forging refers to forging at room temperature, while forging above room temperature but not exceeding the recrystallization temperature is called warm forging. the precision of warm forging is high, the surface is smooth and the deformation resistance is not significant.

the workpiece formed by cold forging at room temperature has high shape and dimensional accuracy, smooth surface, fewer processing steps, and is convenient for automated production. many cold forged and stamped parts can be directly used as parts or products without the need for cutting processing. however, during cold forging, due to the low plasticity of the metal, it is prone to cracking during deformation and has a high deformation resistance, requiring large tonnage forging machinery. the temperature of the blank remains constant throughout the entire forming process. isothermal forging is to fully utilize the high plasticity of certain metals at a constant temperature, or to obtain specific structures and properties. isothermal forging requires the mold and billet to be kept at a constant temperature, which requires a high cost and is only used for special forging processes, such as superplastic forming.

product message

related products

the company has long been committed to all kinds of crushing machine tools, fuselage welding processing, annual welding capacity of more than 20000 tons, can undertake all kinds of machine tool protective cover shell, electrical box and other sheet metal parts.

product classification

contact us

jiangsu yanggu forging machine co., ltd.

--------------

address: runyang south road, yangzhou, jiangsu, china

telephone:

mobile:

after-sales service:

zip code: 225128

mailbox:2318948788@ebuyshop.cc

customer message